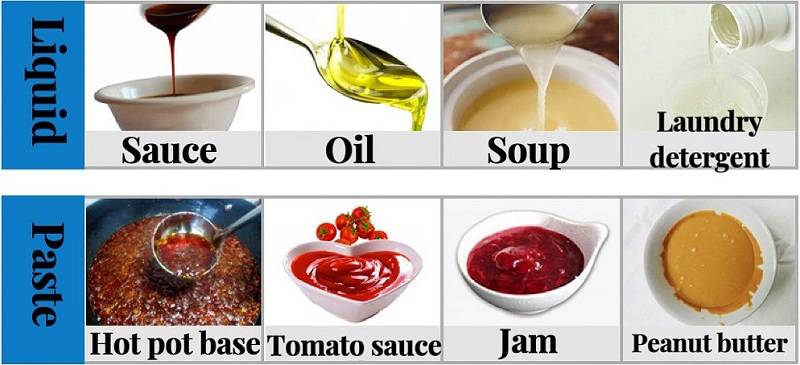

Sauce and Liquid Pipeline Metal Detector for detecting ferrous metal (FE), and non-ferrous metals (copper, aluminum, etc) and stainless steel in sauces and liquids.Easily integrated into existing sealed pipe system, this metal detector is suitable for pump pressure fluid and semi-fluid products such as sauce, liquid, etc.

Detection diameter (mm): 50/63/80

Sensitivity iron: Φ0.5mm/Φ0.6m/Φ0.8m

Sensitivity stainless steel: Φ1.2mm/Φ1.5mm/Φ2.0mm

Alarm method: automatic valve rejector

Pressure requirement: ≥0.5Mpa

Power supply: AC220V (optional)

Main material: SUS304

Inner tube material: food grade tube

High Sensitivity Detection:

Detects ferrous, non-ferrous, and stainless steel metals, providing high sensitivity even for very small metal particles, which is critical for ensuring contamination-free sauces and liquid products.

Automatic Rejection System:

Features an integrated automatic rejection system that efficiently removes contaminated products from the production line, ensuring that only safe, metal-free products reach the packaging stage.

Flow-Through Design:

Optimized for the flow-through nature of liquid and semi-liquid products, allowing for easy integration into production lines where sauces, soups, dressings, and other viscous products are processed.

Durable Construction:

Built with food-grade stainless steel and materials that are resistant to corrosion, ensuring long-lasting performance in liquid food production environments.

Easy Integration:

Designed for simple installation into existing sauce production lines, minimizing the need for major adjustments or downtime during setup.

Detects metal contaminants in a variety of sauces such as ketchup, mayonnaise, hot sauce, BBQ sauce, salad dressing, and pasta sauces.

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

Q1. Are you a manufacturer or trader?

A: We are a manufacturer and we are located in Shanghai,China. We have our own design team for product design.

Q2. What are your company's requirements for payment terms?

A: TT,L/C,Western Union,Money Gram,Paypal,International Credit Card.,

Q3: Can you explain the whole transaction process?

1. Understand the specific needs of customers and determine the machine details.

2. Sign the contract.

3. Pay the deposit.

4. The factory arranges production.

5. Test and inspect the machine before shipment.

6. Check by customers through online or on-site testing.

7. Shipment and transportation, balance payment.

Q4. What kind of shipping method can you provide?

A: By sea, by air and by international express.We will send the photo and video of machine to customer to check the machine running situation before delivery.

Q5. Do you accept customer logo and customization?

A: We accept all kinds of customization and logo for our customers for all our products.

Q6. How about the packing for product? Is it easy damaged during transportation?

A: No.We takes of wooden case and it is very safe.