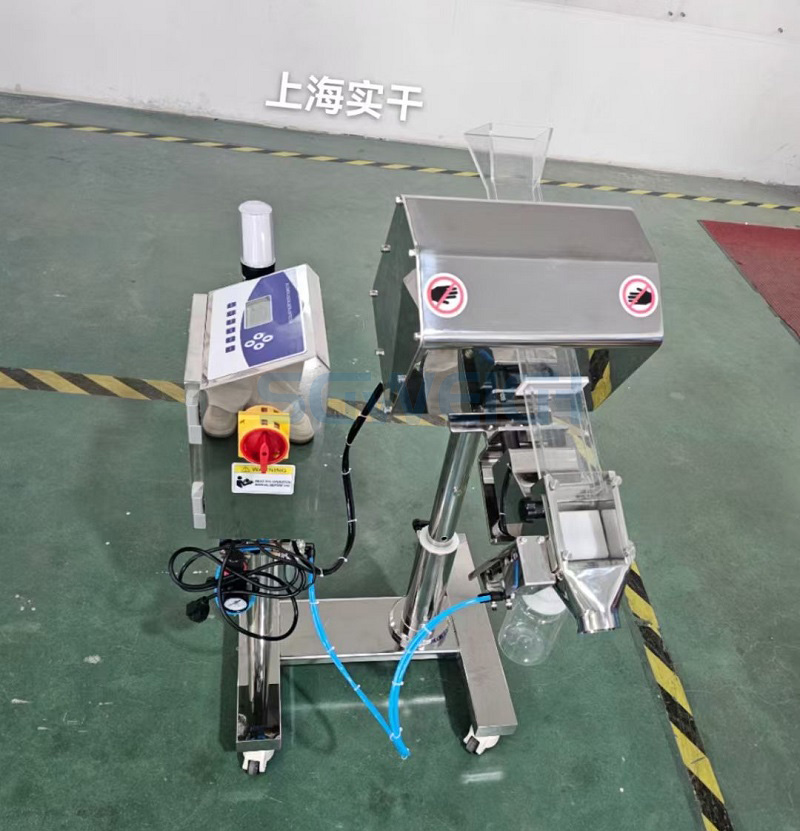

Plastic Granules Gravity Feed Metal Detector Machine reduces operator intervention and production line downtime with advanced features such as an automatic learning system,self-calibration and continuous automatic testing capabilities.Dust-proof, clean-in-place,micro-particle contamination,gravity feeding,and can be customized to meet your pharmaceutical inspection requirements.Industrial Metal Detector Machine with Automatic Reject can be individually adapted to the requirements of the respective production environment.Welcome to consult for quotation information!

SG-YJ60

Feed port height and size: Height: 770-930mm Feed port size: 76mm

Height and size of outlet: Height: 770-860mm Size of outlet: 51mm

Effective passing size: W70*H20mm

Maximum production capacity: 500,000 pcs/hour

Detection sensitivity: Fe: 0.4mm, stainless steel: 0.6mm

Machine weight: 75kg

Removal method: flip culling

Working voltage: 220V/110V, 50/60HZ

Equipment dimensions: 1115*550 (1280-1400) mm

For reference only, please consult for details!

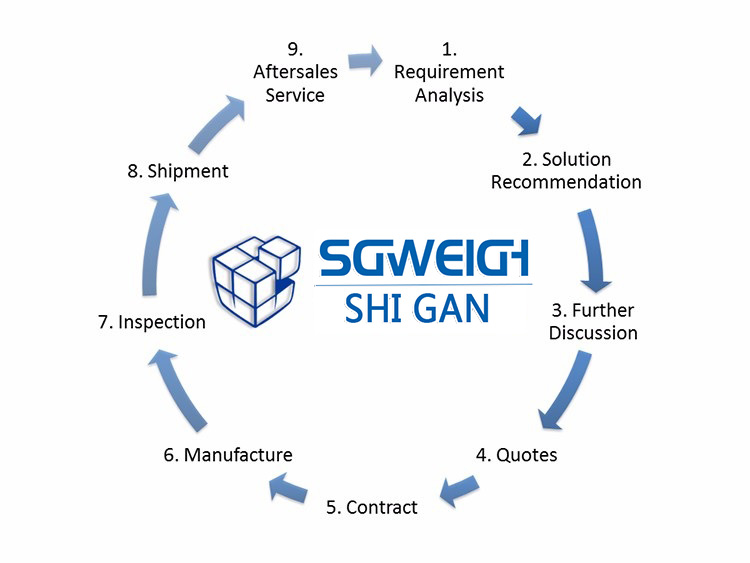

Contact us to recommend a product that is suitable for you!

1.One-button intelligent operation, simple and convenient operation;

2.High-end products, with high precision, high sensitivity,Used to separate magnetic and non-magnetic metals from free-falling bulk materials.

3.It can handle various types of medicines. In order to save space, a more compact rack design is adopted.

4.For health and safety, the metal detector is made of food-grade SUS304 stainless steel;

5.Can automatically recognize product characteristics and effectively eliminate product effects;

6.The height of the probe is adjustable, and it can be customized for higher height.

7.Able to detect ferrous, non-ferrous or stainless steel, even in tiny quantities.

8.Fully FDA compliant, with in-built security and data control.

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

1.Product quality commitment

(1).There are quality records and testing data for the manufacture and testing of products.

(2).For the inspection of product performance,we sincerely invite users to inspect the whole process and performance of the product in person.After the product is confirmed to be qualified,it will be packaged and shipped.

2.the product price commitment

Under the same competitive conditions, our company will sincerely provide you with a preferential price on the basis of not reducing the technical performance of the product or changing the product components.

3. Delivery time commitment

Product delivery time: as far as possible according to user requirements,if there are special requirements, it needs to be completed in advance,and strive to meet user needs.