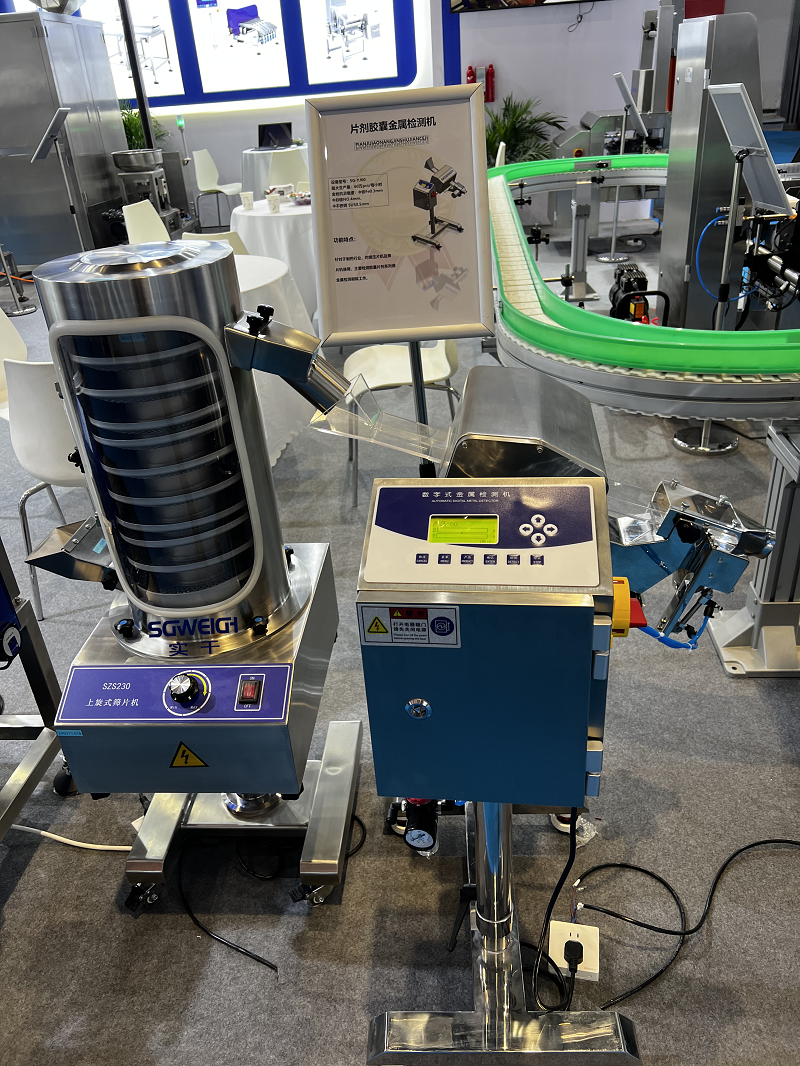

Pharma Metal Inspection Machine is a key quality control equipment used to detect metal impurities that may be mixed into pharmaceutical raw materials, finished products or production processes.These impurities may come from raw material contamination, equipment wear or human negligence, which may affect the safety of the drug.Metal Detector for Tablets Capsules Pills Drugs can be connected to tablet compressors and capsule filling machines.

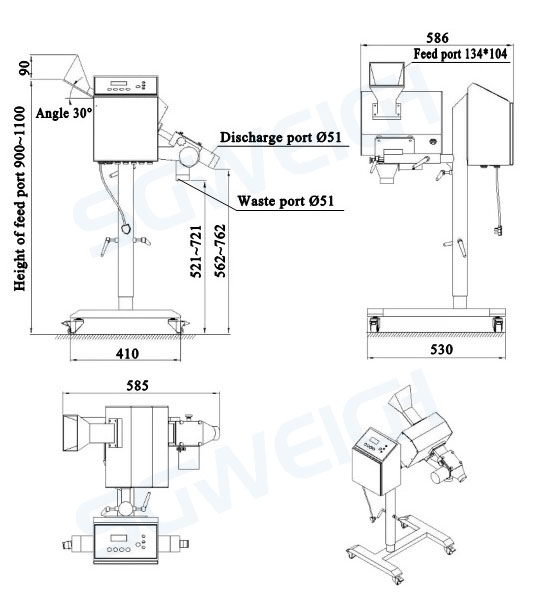

Type:SG-M50

Feed port height and size: Height: 770-930mm Feed port size: 76mm

Height and size of outlet: Height: 770-860mm Size of outlet: 51mm

Effective passing size: W70*H20mm

Maximum production capacity: 500,000 pcs/hour

Sensitivity(adjustable or not):Yes

Detection sensitivity: Fe: 0.4mm, stainless steel: 0.6mm

Machine weight: 75kg

Removal method: flip culling

Working voltage: 220V/110V, 50/60HZ

1. Suitable for detecting magnetic and non-magnetic metal foreign objects in separated capsules or tablets.

2. Product tracking function: It can automatically make internal adjustment compensation according to the change of product effect.

3. Using the latest micro-processing control system, it has the function of automatic learning and setting.

4. The metal detection coil is made of stainless steel, and the inside is completely sealed, with stable performance.

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.