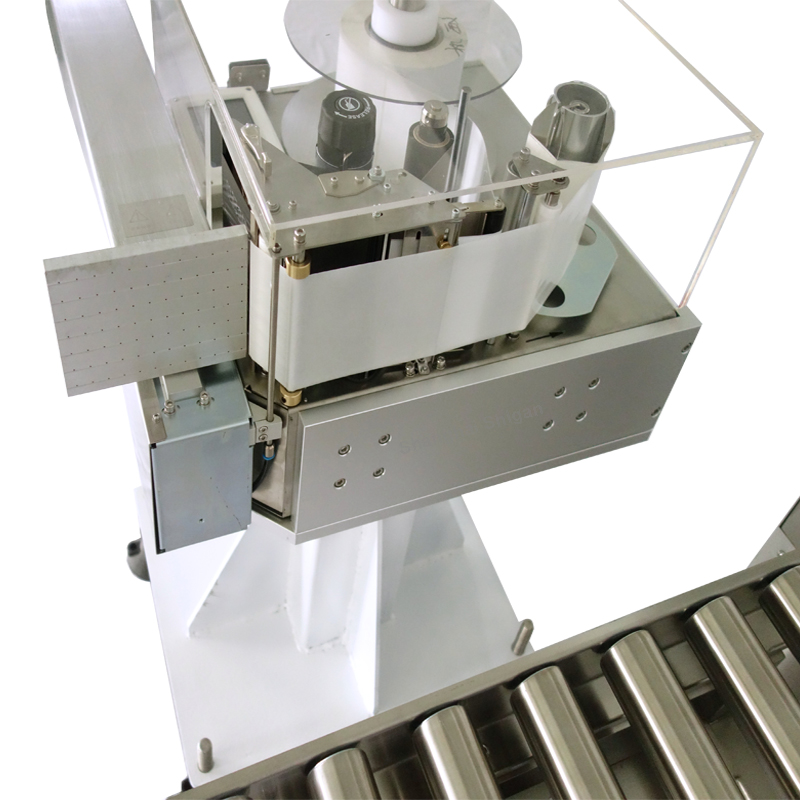

High-Accuracy Weighing and Labeling Machine is a machine suitable for retail, trade and industrial industries.This automatic weighing machine can meet the diversified needs of customers for weighing and labeling,and provide advanced solutions.The Beverage Bottle Weight Labeler does not take up a lot of space,and the compact body design helps you save production space.

Weighing range: 5g - 1500g

High detection accuracy: ± 0.5g (the larger the weight, the faster the speed, the worse the accuracy, depending on the size, speed and weight of the product)

Small scale: 0.1g

Belt width: 220mm

Belt height from the ground: 800mm ± 50mm

Conveying speed: 20-60 m/min (variable frequency speed regulation)

Detection speed: 60~120 pieces/minute

Conveying direction: facing the screen from left to right

Power supply: 220V 50-60HZ

External air source: 0.6-1Mpa

Pneumatic interface: ¢ 8mm

Power: about 200W

Overall dimension: about 1543mm (L) * 721mm (W) * 1470 ± 50mm (H)

Main engine weight: about 100Kg

For reference only, please consult for details!

Contact us to recommend a product that is suitable for you!

1. Program storage function: users can preset the setting parameters for various products (such as label quantity, delay, alarm processing method, etc.) to control

In the system of computer, it can be used when the production needs to be changed without resetting.

2. Multiple labeling methods: pneumatic, blowing, sweeping and other methods are available for users to choose, which can meet the labeling requirements of different occasions/different items.

Counter function: various counter functions are convenient for users to understand and follow up production, material status, label usage, etc. Different counting methods can greatly improve the flexibility of users for different production and statistical needs.

3. Alarm function: when a fault occurs, the system will pop up corresponding alarm information or shut down, so that users can clearly understand the fault situation. (Optional alarm modes include: "close/open" signal and "stop/do not stop" command).

4. Real-time printing and labeling leak-proof labeling function, and automatic label filling (reprinting) function can be selected to meet the special needs of the production line.

5. Flexible editing software: compatible with most Chinese/English label editing software, printing content editing has strong flexibility.

6. Extended function: It can connect other equipment (such as barcode reader, electronic bang, detection equipment or other industrial equipment) to form an integrated system to meet the application requirements of users' complex production management and logistics monitoring.

7. Connection function: connect with the main system through Ethernet to achieve the purpose of real-time management and system integration, and eliminate the need for on-site configuration control computer.

Easy to use: The touch screen is easy to use with a user-friendly Chinese-English bilingual user interface.

8. Easy installation: stand up and easy adjustment; Large tolerance of object distance reduces the need for fine adjustment during installation.

Our products can be shipped by sea, air and land.

Based on the spirit of pursuing high-quality products and customer satisfaction, Shanghai Shigan Industrial Co,.Ltd solemnly promises you with the principles of preferential prices, considerate service and reliable product quality.

1.Product quality commitment:

(1). The manufacturing and testing of products have quality records and testing data.

(2). For product performance testing, we sincerely invite users to personally check the whole process and performance of the product, and then pack and ship the product after it is confirmed to be qualified.

2. Product price commitment:

Under the same competitive conditions, our company will sincerely provide you with preferential prices on the basis of not reducing product technical performance or changing product components.

3. Delivery time commitment:

Product delivery time: Try to meet user requirements. If there are special requirements, it needs to be completed in advance, and strive to meet user needs.

Multi-level Sorting Checkweigher

Checkweigher and Metal Detector Combo