Gravity Free-Fall Metal Detector is a type of in-line inspection system used to detect and reject metal contamination in bulk, free-flowing products as they fall under gravity. It’s especially common in the food, pharmaceutical, chemical, and plastic industries for powders, granules, or small pieces.

Detection Method:Balanced coil

Sensitive adjustment:Automatic or Manual

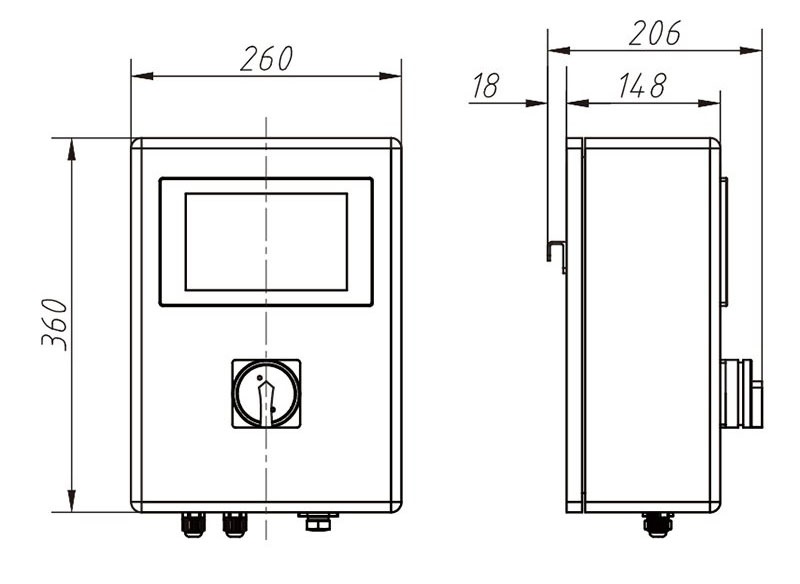

Detection sensitivity: Fe: 0.4mm, stainless steel: 0.8mm(depend on product and speed)

Operation Panel:Key Pad

Material of Construction:304 Brushed stainless steel

Rejecting Mode:Sound and light alarm/Auto-Flap Rejector

Application:Ideal for pre-packaging inspection of bulk, powder and granule products

IP Rating:65

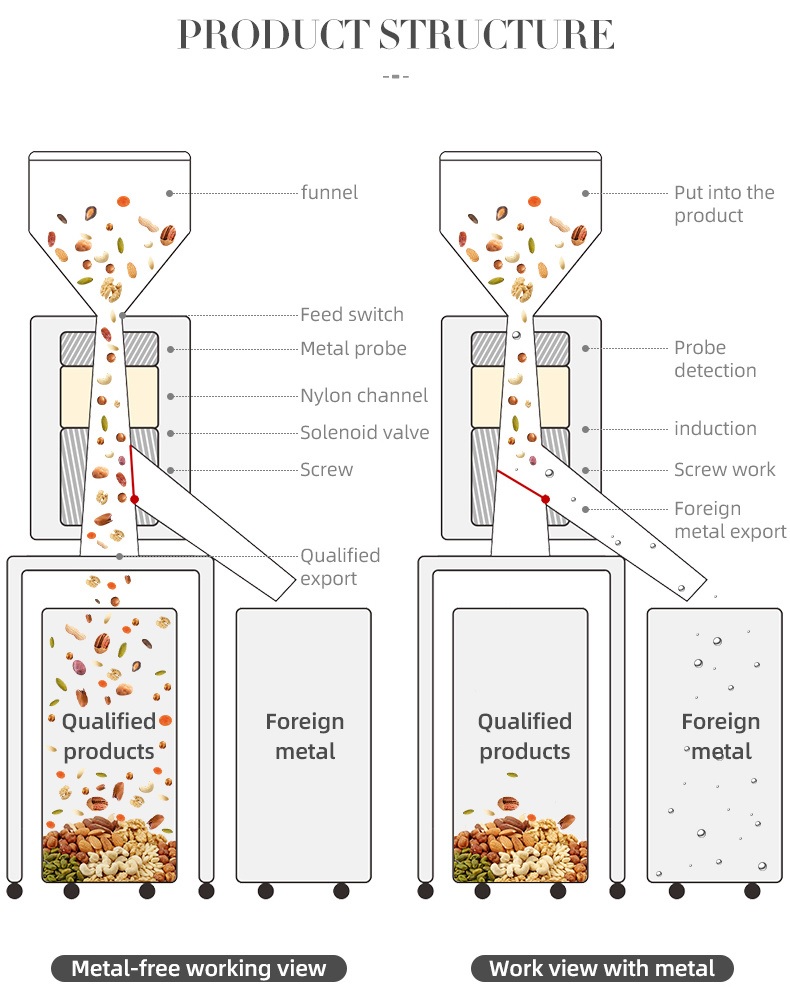

1. Collection of detection coil, controller, separation device.

2. It can save losses of material, because rejection board rapidly rejects unqualified material.

3. Easy operation and Space-saving, compact design guarantees quick installation.

4. Properties of detection material: dry, good liquidity, no long fiber, no conductivity.

5.Various types of caliber can be chosen, which can meet all practical applications.

6. It is mainly used for detection of loose granule materials. Those materials fall into detection coil with gravity. The machine can be applied in plastic, food, chemical industry and so on.

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

TAGS:

Capsule Checkweigher

Multi-Lane Check Weigher

Pharmaceutical Checkweigher

Capsule Tablet Metal Detector