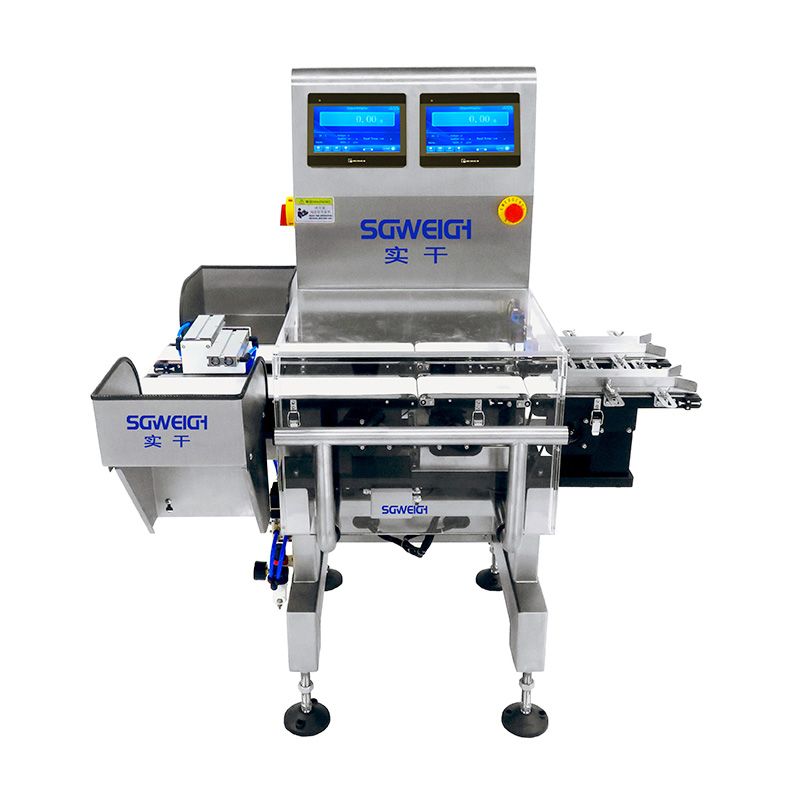

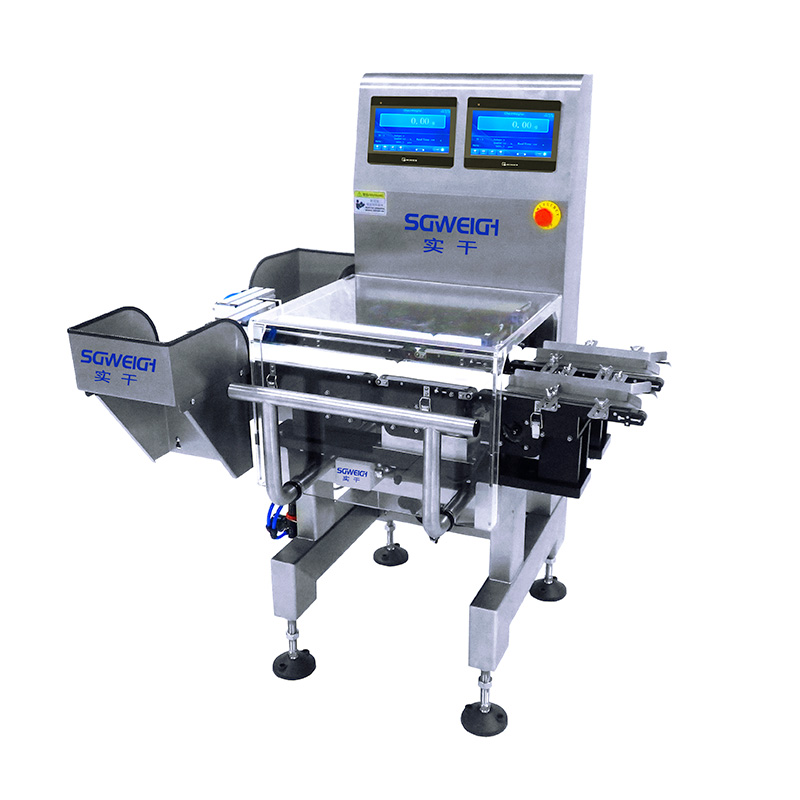

The space-saving dual-lane configuration allows you to inspect two lanes of products with one unit.Dual-lane Checkweighers are typically placed after filling and packaging machines of sticks, tubes, pouches, and flow-wrapped products. Each line can be operated independently from the machine's touchscreen panel.

Model: SG-2X

Weighing range: 1-50g

Product restrictions: L:180 W-40 H:2-20(mm)

Sorting accuracy: ±0.01g (Depends on products)

Graduation value: 0.01g

Maximum speed: 70pcs/min

Belt width: 100mm

Machine weight: about 50kg

Power supply: AC220V±10%50HZ

Power: about 100W

Main material: SUS304

1. One machine is equipped with 2 touch screens and 2 weighing channels, 2 rejection systems, which do not interfere with each other and weigh independently.

2. Lifting type rejection of unqualified products.

3. Multiple channels can be customized to improve production efficiency.

4. Chinese and English operation interface.

5. Built-in report statistics. Keep track of production status at any time.

6. Three-level operation authority management, support for self-set passwords.

7. Can weigh various products.

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

Tag:Dual-lane Checkweigher,Multi-Lane Checkweigher