New Automatic Industrial Checkweighers have a conveyor belt that transports the products to be weighed. As the products pass through the machine, they are weighed using a load cell or other weight sensing mechanism. The weight data is then compared to a preset weight limit or target weight.

If the product is within the acceptable weight range, it will continue along the conveyor belt to the next processing or packaging stage. However, if the product is over or under the specified weight, the High Precision In-Motion Check Weighing System will activate a mechanism such as an ejector, pusher, or diverter to remove the product from the line. This ensures that only products within the required weight range can move on, maintaining quality control and complying with regulations.

They help streamline production processes by automatically sorting products based on weight, minimizing human error and ensuring consistent output.

Type:SG-100

Weighing Range:2-300g

Limited of product:L:100 W:100 H:2-150mm

Accuracy:±0.05g Depend on products

Division Scale:0.01g

Belt Speed:0-90m/min

Max Speed:260 pcs/min

Belt Width:100mm

Machine Weight:70kg

Power Supply:AC 110/220V ±10% 50HZ

Power:100W

Main Material:SU304 stainless steel

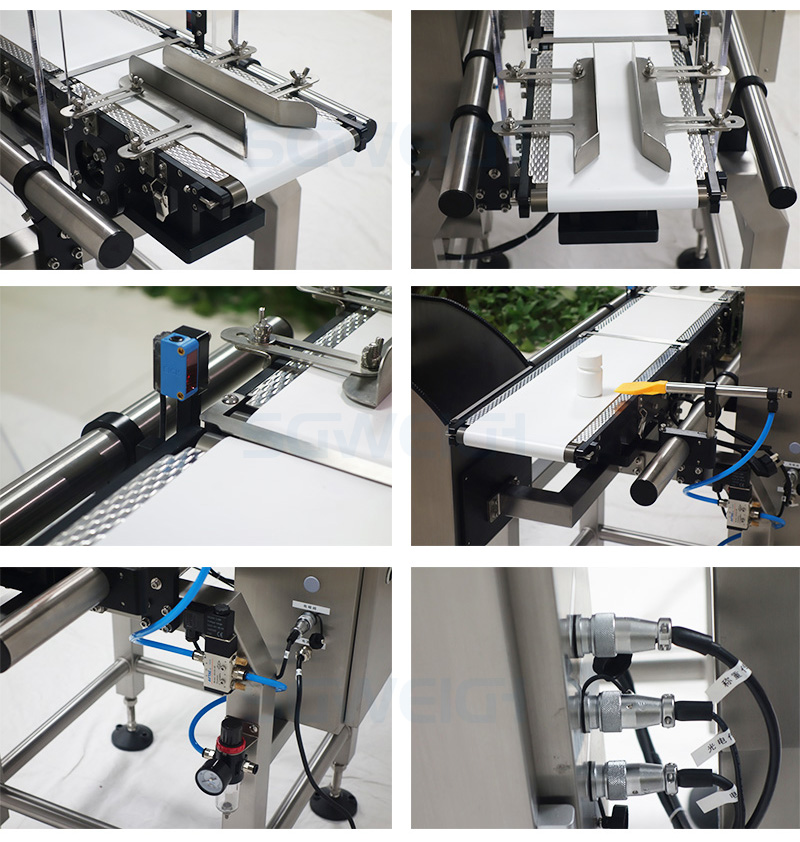

● Strong stainless steel 304 structure.

● Reliable and stable weighing control system.

● High speed digital filter processing and automatic zero tracking function.

● Humanized operating system, easy to learn and operate.

● Operation display: 7/10 Inches Color Touch Screen.

● Product Storage: 100 kinds of product preset.

● Weighing data output: USB port to download data into Excel.

● Rejecting system: Pusher, Lever/Flapper, Air Jet, Slide available for choice.

Q1. Are you a manufacturer or trader?

A: We are a manufacturer and we are located in Shanghai,China. We have our own design team for product design.

Q2. What are your company's requirements for payment terms?

A: TT,L/C,Western Union,Money Gram,Paypal,International Credit Card.,

Q3: Can you explain the whole transaction process?

1. Understand the specific needs of customers and determine the machine details.

2. Sign the contract.

3. Pay the deposit.

4. The factory arranges production.

5. Test and inspect the machine before shipment.

6. Check by customers through online or on-site testing.

7. Shipment and transportation, balance payment.

Q4. What kind of shipping method can you provide?

A: By sea, by air and by international express.We will send the photo and video of machine to customer to check the machine running situation before delivery.

Q5. Do you accept customer logo and customization?

A: We accept all kinds of customization and logo for our customers for all our products.

Q6. How about the packing for product? Is it easy damaged during transportation?

A: No.We takes of wooden case and it is very safe.

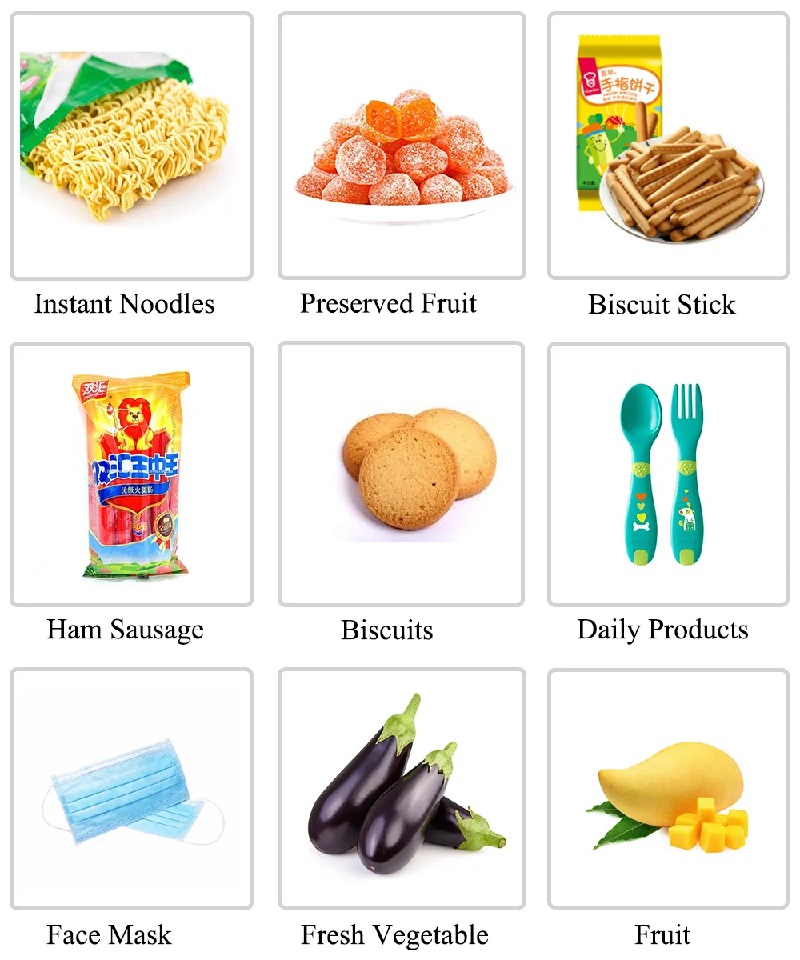

Please tell us the following information while you send us an inquiry. Base on your message, we will suggest the optimum solution to you for reference.Thank you.

●What product?

●Product weight?

●Product size?

●Speed requirement?

●Accuracy requirement?