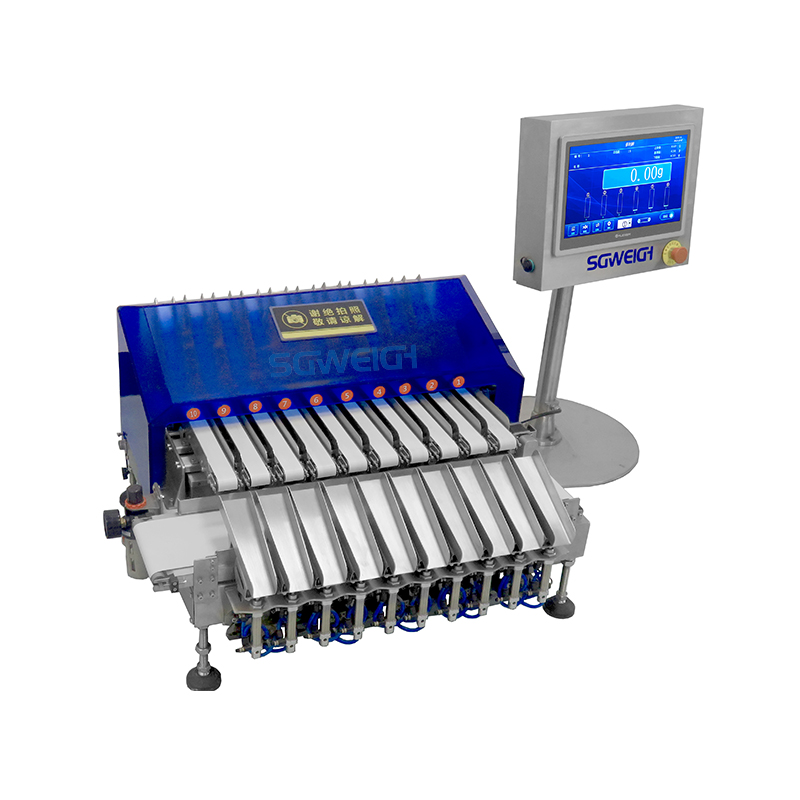

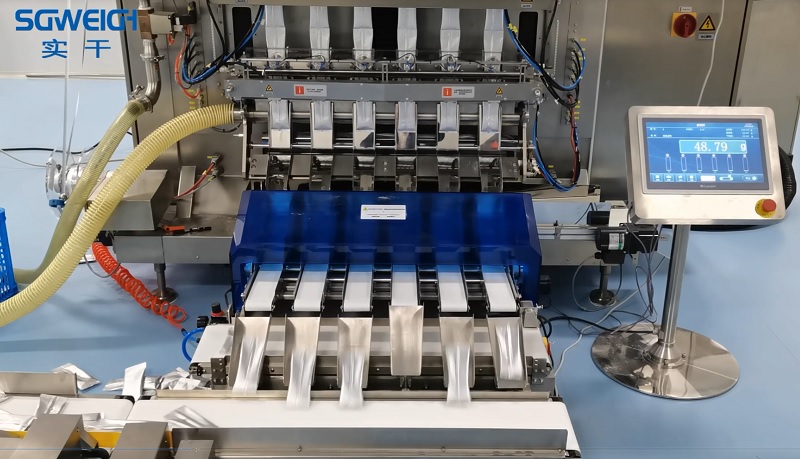

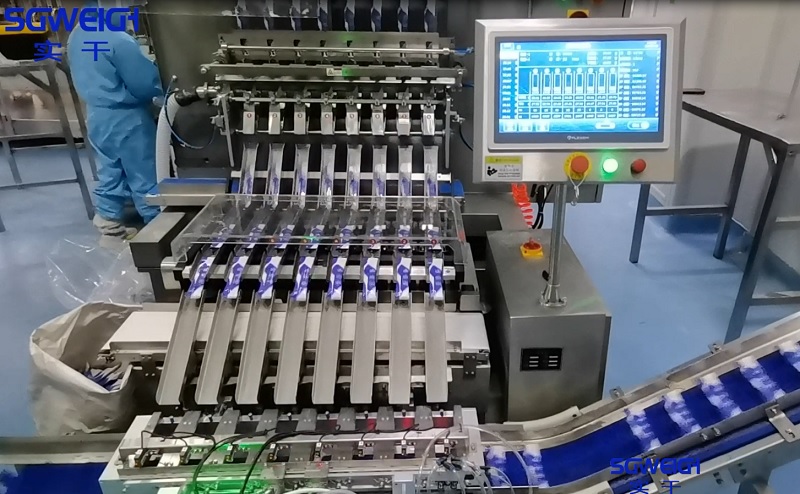

Multi-lane Checkweigher for Separate Stickpack Pouches can be configured with multiple conveyors. This increases speed without decreasing accuracy or repeatability.Connects the discharge port of multi-lane packaging machine,checkweighs long strip soft bags of each lane, andrejects underweight or overweight products to unqualifiedcollection area.Can also join cartoning machine directly.

Type:SG-10X

Weighing scope:2-300g

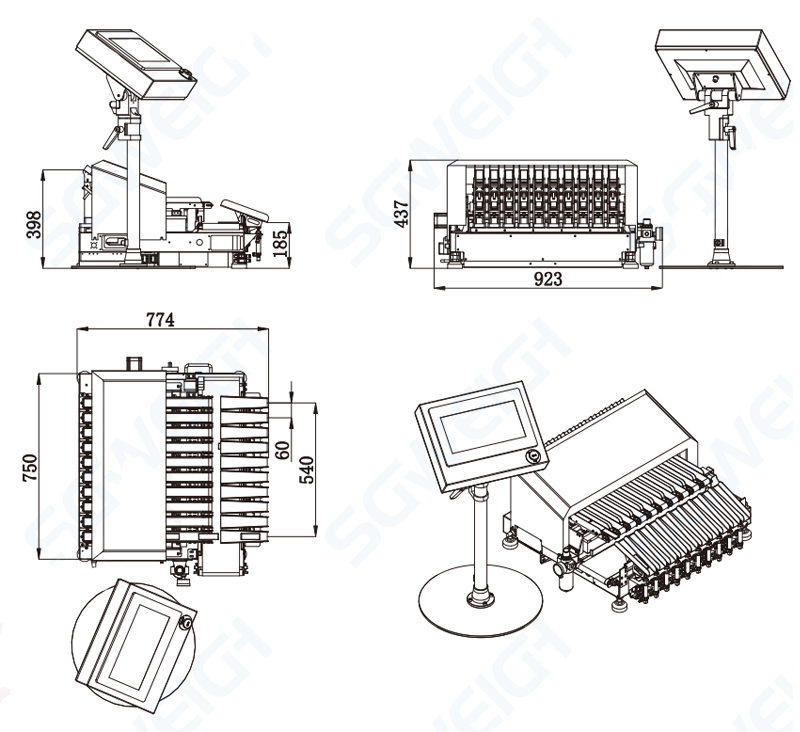

Restrictions of product:L:180 W:40 H:2-20(mm)

Accuracy:±0.01g (Depends on products)

Division scale:0.01g

Belt width:30mm

Highest speed:70pcs/min(one lane)

Weight of machine:about 200Kg

Powder supply:AC220V 50HZ

Power:about 300W

Main material:SUS304(Stainless Steel)

Multi-channel passing products to improve production efficiency

(the number of channels can be customized)

Multi-Conveyor Line Weighing Scale

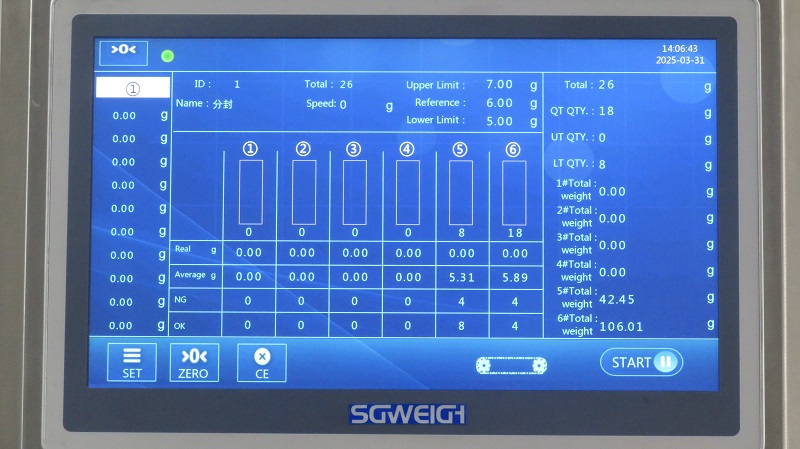

1. Large-size color LCD touch screen human-machine interface, easy to operate and intuitive display.

2. Support multiple languages: custom language, default Chinese and English.

3. Can store 100 kinds of product test data, convenient for users.

4. USB data storage interface, report data can be transferred to PC for analysis and printing.

5. Parameter setting password protection, only management personnel can operate.

6. Automatic zero-point tracking system to ensure reliable test data.

7. Data external communication interface, can be connected to other equipment on the production line (such as: multi-row packaging machine, metal detector) (customized by customers).

8. Simple mechanical structure, easy to disassemble, clean and maintain.

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.