The Capsule Dynamic Checkweigher is a high-precision, high-speed dynamic weighing device specifically designed for 100% online weight detection after the capsule filling process in the pharmaceutical industry. Integrated into the capsule production line, it weighs, judges, and automatically sorts and removes defective capsules in real time, making it a key quality control device to ensure that drug fill weight variations meet requirements.

Type:SG-JN10

Weighing scope:5-2000mg

Display scale:0.1mg

Highest sorting accuracy:±0.5mg

Product specification:Capsule-00#-5#/Wafer-Φ5.5-Φ18mm/Thickness-3-12mm/Pill-Φ5.5-Φ12mm(Other sizes or shapes subject to testing)

Highest sorting ability:100000 PCS/HRPCS/HR

Number of columns:10 Columns

Power supply:AC-220V±10%, 50HZ

Compressed air:0.3-0.9Mpa

Use environment:15~30°C (The temperature change during use should not exceed the range of 1°C/h.Humidity:30-70%(but no condensation)

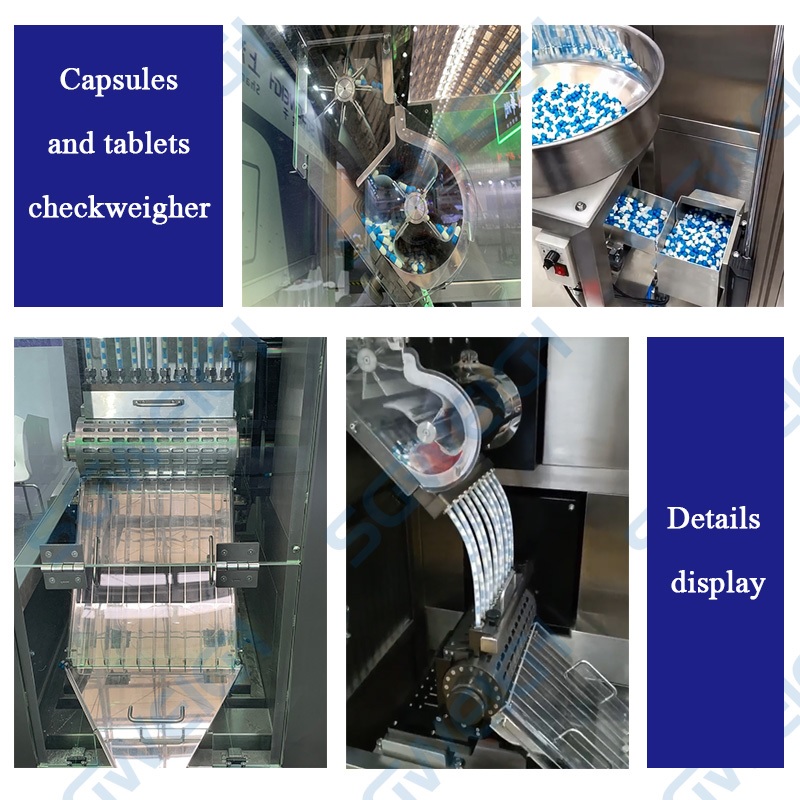

1. Loading and Arranging

The filled capsules are arranged in an orderly manner by an elevator and fed into the conveyor system of the checkweigher in multiple rows.

2. High-Speed Separation

Through a specific mechanical structure (such as belt gaps), the tightly packed capsules are separated into individual capsules, ensuring that each capsule is in an independent and undisturbed state during weighing.

3. Dynamic Weighing

The separated capsules pass through a weighing module. Sensors capture the weight signal of the capsules in a very short time.

4. Signal Processing and Judgment

The weight signal is collected by a high-speed processor and compared with preset upper and lower weight thresholds. The equipment automatically determines whether the capsules are "qualified," "overweight," or "underweight."

5. Real-Time Sorting and Rejection

Based on the judgment result, when the capsules reach the rejection point, the equipment uses a flip-plate rejection system to accurately drop the unqualified products into the waste bin, while qualified products continue to the next process.

● Our machines undergo comprehensive testing and commissioning before shipment to ensure stable and reliable performance.

● Equipment is packaged in thickened wooden crates with shock and moisture-proof interiors to effectively prevent damage during transportation.

● We partner with several professional international logistics companies and support a variety of shipping methods, including sea, air, and land transport.

● Ensure the equipment arrives safely and on time at your facility.

High-Speed Inline Rotary Checkweigher