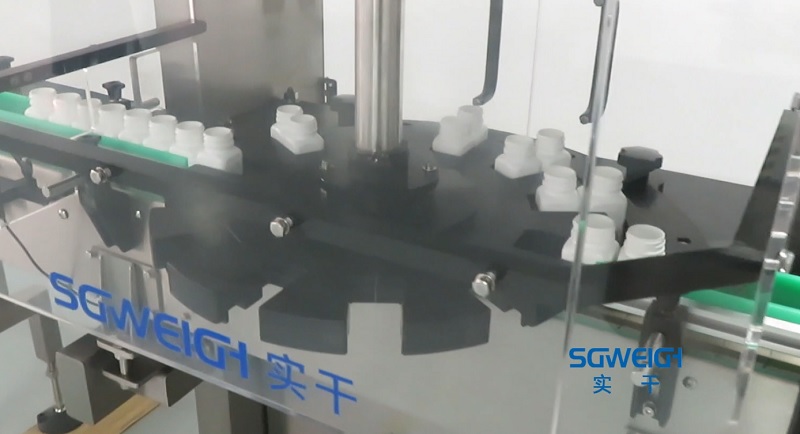

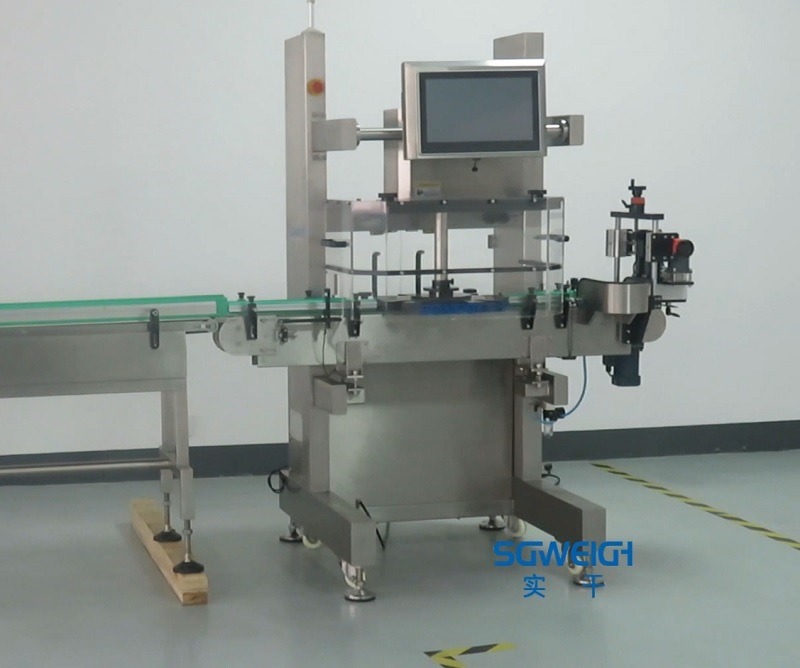

The Rotary Bottle Checkweigher is an automated machine used on production lines to ensure that bottles are filled with the correct weight of product.The Online Candy Can Weight Checker picks the product directly from the conveyor and uses an alternating feed rotary system to position and stabilize the product on a static weighing plate, achieving optimal levels of accuracy and repeatability at high production speeds.

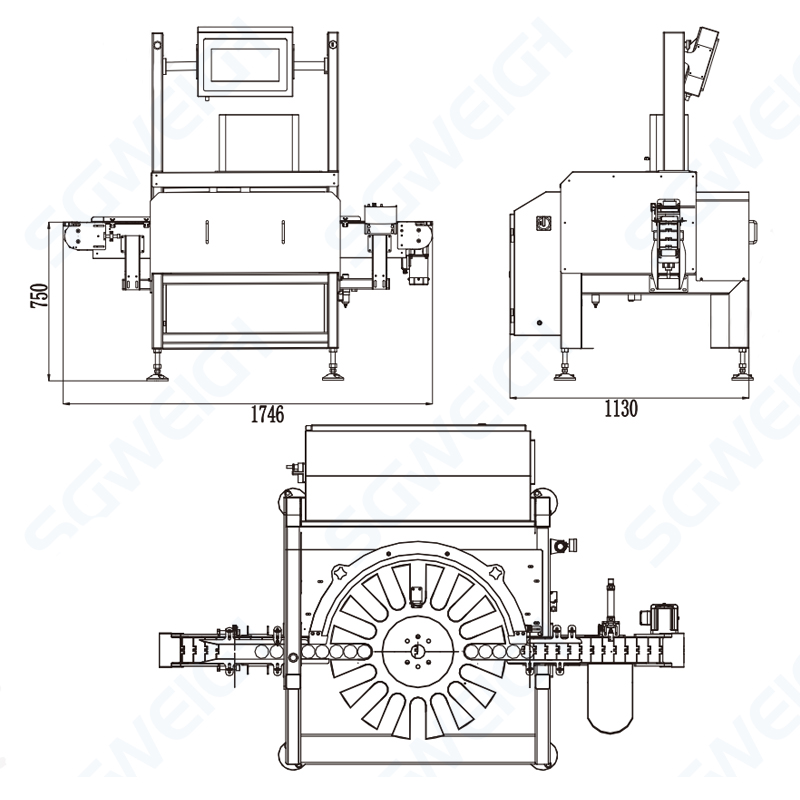

Model: SG-Z2 (dual channel)

Weighing range: 5-300g

Minimum scale: 0.01g

Sorting accuracy: ±0.02 grams (depending on the product)

Sorting speed: maximum 50 pieces/minute (single channel)

Conveying speed:0-50m/min

Operation mode: touch operation

Rejection method: air blowing removal/push plate removal

Machine structure: stainless steel (SUS304)

Power supply: 220V 50-60HZ

◎Large screen display,clear viewing and convenient operation.

◎Default Chinese and English operation interface.

◎Photoelectric positioning,the turntable accurately delivers the product to the weighing sensor.

◎The chain conveyor is strong and durable.

◎Three-level operation authority management,support special password setting.

◎100 product formula preset storage.

◎Automatic elimination of unqualified products.

◎Multiple channels pass products to improve production efficiency (the number of channels can be customized).

Checkweigher for small to medium-sized cylindrical packaging such as bottles, jars and cans.

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

TAGS

Capsule Checkweigher

Multi-Lane Check Weigher

Pharmaceutical Checkweigher

Capsule Tablet Metal Detector