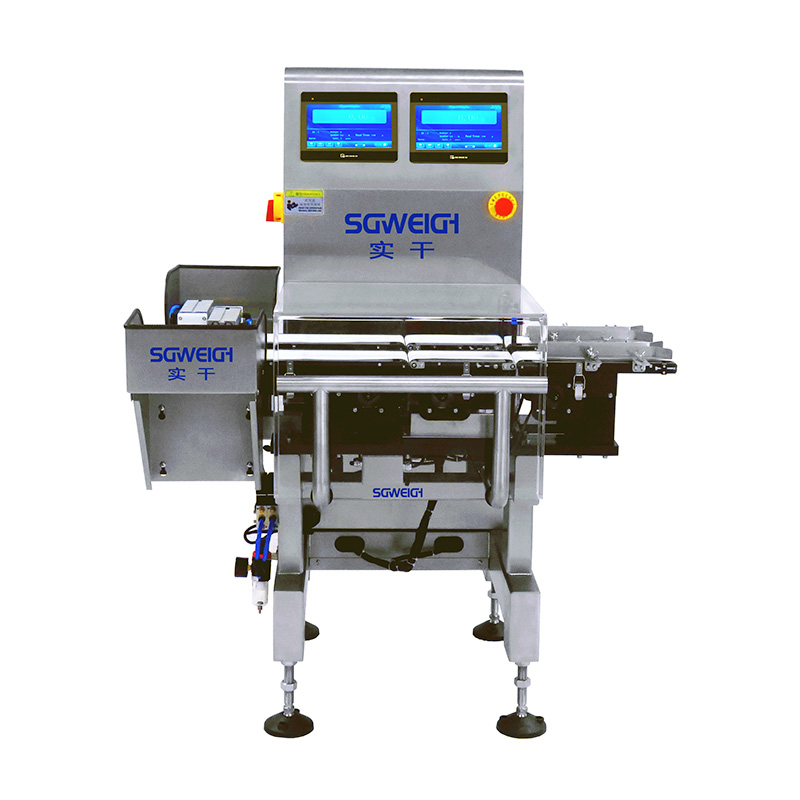

High Speed Dual-lane Checkweigher is a high-speed industrial weighing system designed to simultaneously weigh products in two parallel lanes, doubling throughput while maintaining accuracy.Small Package 2 Lines Conveyor Belt Scale is commonly used in food, pharmaceutical, and packaging industries where high-speed production lines require efficient quality control.

Model: SG-2X

Weighing range: 1-50g

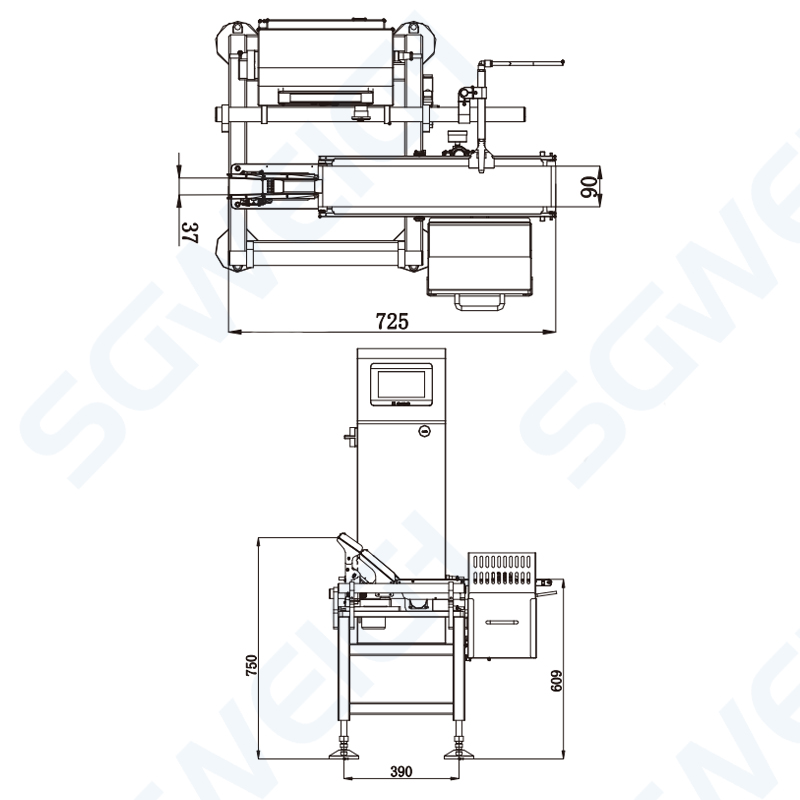

Product restrictions: L:180 W-40 H:2-20(mm)

Sorting accuracy: ±0.01g (Depends on products)

Graduation value: 0.01g

Maximum speed: 70pcs/min/lane

Belt width: 100mm

Machine weight: about 50kg

Power supply: AC220V±10%50HZ

Power: about 100W

Main material: SUS304

1. High-Speed Weighing

Handles 120+ products per minute (combined for both lanes).

Ideal for fast-moving production lines (e.g., snacks, beverages, pharmaceuticals).

2. Independent Lane Control

Each lane operates independently, allowing different weight tolerances if needed.

If one lane fails, the other can continue running (minimizing downtime).

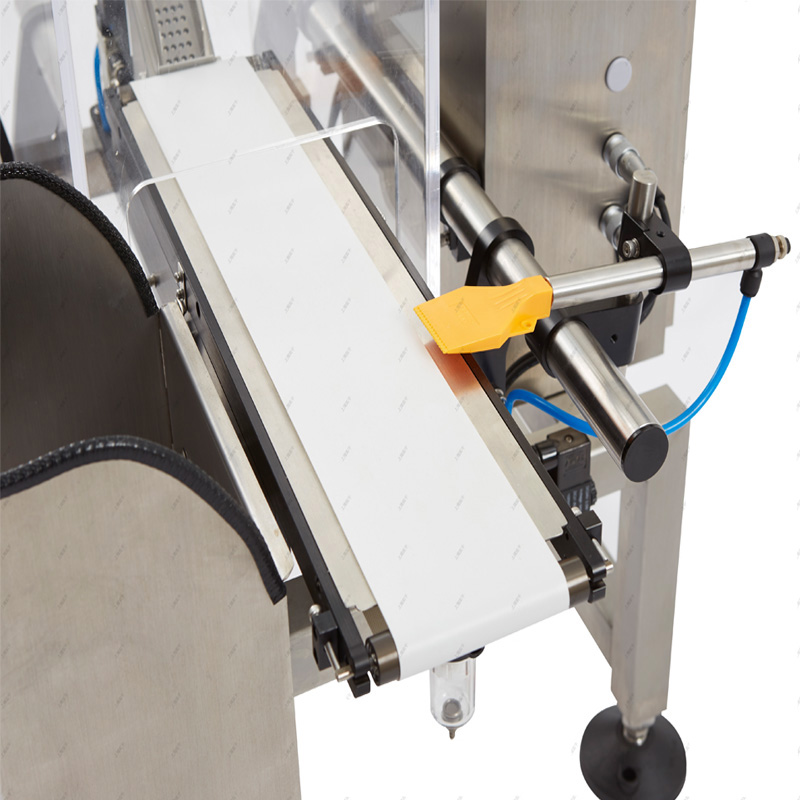

3. Advanced Rejection Systems

Pneumatic pushers (for gentle product handling).

Air blast rejectors (for lightweight items).

Flap gates or sliding diverters (for larger products).

4. Data Tracking & Reporting

Batch reporting for compliance (FDA, ISO, HACCP).

Integration with ERP/MES systems for production analytics.

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

TAGS:

Capsule Checkweigher

Multi-Lane Check Weigher

Pharmaceutical Checkweigher

Capsule Tablet Metal Detector