Capsule Check Weigher is a specialized weighing machine used in the pharmaceutical industry to ensure the weight consistency of individual capsules,which is critical for quality control, regulatory compliance, and dosage accuracy.

How a Capsule Inspection Machine Works

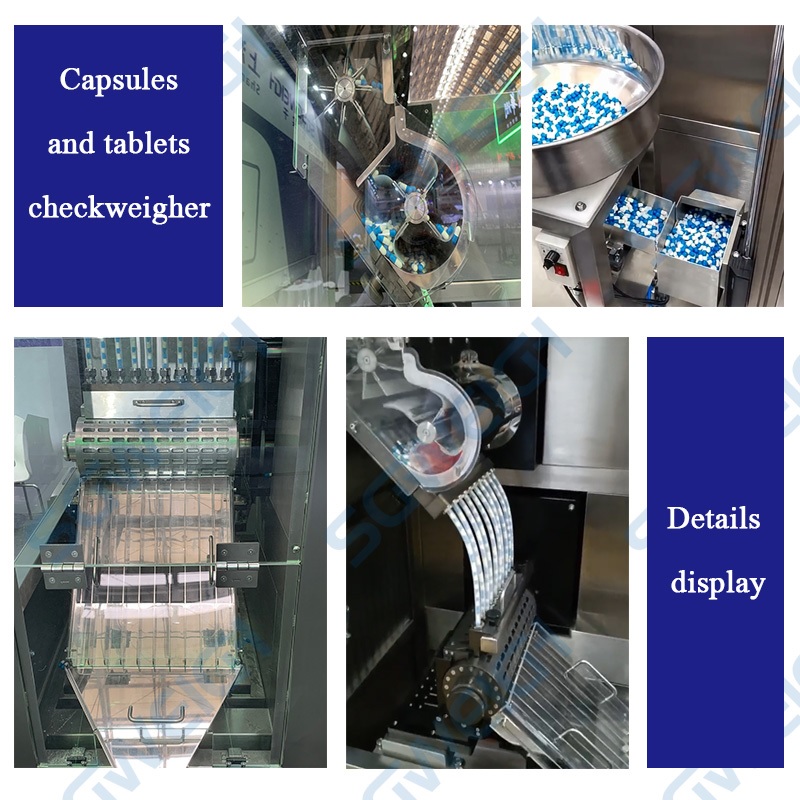

Feeding System – Capsules are fed into the machine via a vibratory bowl or conveyor.

Weighing Mechanism – Each capsule is weighed individually using high-precision load cells.

Sorting/Rejection System – Capsules outside the acceptable weight range are automatically rejected.

Data Recording – Weight data is logged for batch traceability and quality assurance.

Max throughput (10 lanes)75000 capsules/h

Max throughput (20 lanes)150,000 capsules/h

Max throughput (30 lanes)230,000 capsules/h

Weigh range:2-2000 mg

Highest sorting accuracy:±0.5mg

Scale interval:0.1 mg

Preset memory : 100

Weight of Machine :350kg/500kg/700kg

Power supply:AC-220V±10%, 50HZ

Compressed air:0.3-0.9Mpa

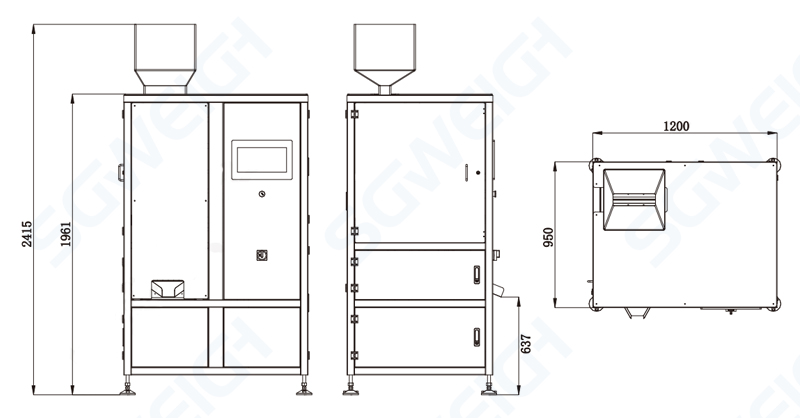

Dimensions:1740 mm H x 866 mm W x 639-1296 mm L (varies by lane amounts)

◎Large screen display, clear viewing, easy operation.

◎Default Chinese and English operation interface.

◎Applicable to conventional capsules and tablets.

◎Can actually display the relevant data of each channel.

◎Three-level operation authority management, support self-set password.

◎100 product formulas are preset and stored.

◎The capsules put into the feed hopper are divided into multiple channels by the silo and transported, weighed and sorted at high speed.

Pharmaceutical Manufacturing – Ensures dosage uniformity in hard/soft gelatin capsules.

Nutraceuticals & Supplements – Checks weight consistency in vitamin or herbal capsules.

Quality Control Labs – Used for sampling and batch testing.

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.

Q1. Are you a manufacturer or a trader?

A: Shanghai Shigan Industrial Co., Ltd. is a manufacturer located in Shanghai,China. We have our own product design team and factory.

Q2. How many types of checkweighers do you have?

A:Our company has a variety of models of checkweighers, suitable for most products and can be applied to almost all industries. Our company's checkweighers can be customized according to demand.We have standard checkweighers, bottle checkweighers, multi-lane checkweighers,tablet capsule checkweighers, box checkweighers,heavy object checkweighers and so on.

Q3. What factors should be considered when choosing a checkweigher?

What is the product you want to weigh?

How many grams/mg/kg of the product?

What is the size of the product?

What are the speed requirements?

Accuracy requirements?

Based on the above information, our sales will recommend the most suitable checkweigher for you.

Q4. How much does the capsule checkweigher cost?

A:There is no quick,easy answer to this question.Our machines are customer-specific, so "standard pricing" is not usually available.Pricing depends largely on your unique needs,such as the product you want to weigh, the size of the product,the speed you want to achieve,or the complexity of the process.Contact us to get a specific quote.

Q5. What kind of shipping methods can you provide?

A: Sea, air and international express. We will send photos and videos of the machine to customers before delivery to check the operation of the machine.

Q6. Do you accept customer logos and customizations?

A: We accept all kinds of customization and logos for all products.

Q7. How is the product packaging?Is it easy to be damaged during transportation?

A: No. We use wooden boxes, which are very safe.

Tag:Tablet Capsule Check Weigher,Capsule Inspection Machine