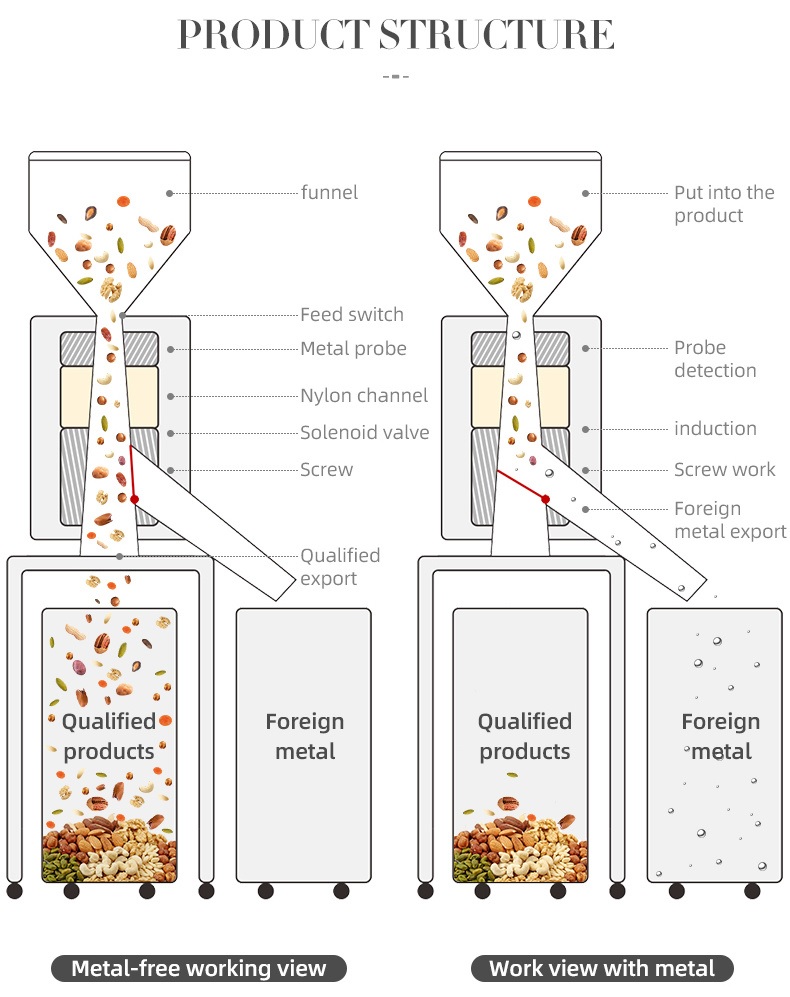

Fully Digital Intelligent Bulk Material Gravity Drop Metal Detector Machine is designed to be used in gravity-falling bulk material environments to detect and remove metal-contaminated products.The gravity drop metal detection system can be used for various bulk materials,whether they are refined bulk materials or raw materials,and even larger irregular objects can be detected.The system integrates a rejection device to remove bulk materials containing foreign matter.Welcome to consult for quotation information!

Feed port height and size: Height: 770-930mm Feed port size: 76mm

Height and size of outlet: Height: 770-860mm Size of outlet: 51mm

Effective passing size: W70*H20mm

Detection sensitivity: Fe: 0.4mm, stainless steel: 0.6mm

Machine weight: 75kg

Removal method: flip culling

Working voltage: 220V/110V, 50/60HZ

Equipment dimensions: 1115*550 (1280-1400) mm

1.One-button intelligent operation, simple and convenient operation;

2.High-end products, with high precision, high sensitivity,Used to separate magnetic and non-magnetic metals from free-falling bulk materials.

3.It can handle various types of bulk products. In order to save space, a more compact rack design is adopted.

4.For health and safety, the metal detector is made of food-grade SUS304 stainless steel;

5.Can automatically recognize product characteristics and effectively eliminate product effects;

6.The height of the probe is adjustable, and it can be customized for higher height.

7.Able to detect ferrous, non-ferrous or stainless steeleven in tiny quantities.

8.Automatic rejector separate the metal objects mixed in material.

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.