Fully Automatic High-Precision Metal Detector Machine have extremely high stability and the ability to eliminate product effects.You can independently set the detection parameters of specified products,simplify the parameter setting process,and automatically store 100 product parameters.Any OEM and customer design orders are welcome! If you are interested in our Textile Clothing Broken Needle Foreign Matter Metal Detector Machine,please feel free to contact us.

Type:SG-M400

Detection sensitivity: in empty state

H-100mm: Fe≥Φ0.8mm, Non-Fe≥Φ1.5mm, SUS≥Φ1.5mm

H-120mm: Fe≥Φ0.8mm, Non-Fe≥Φ1.5mm, SUS≥Φ2.0mm

H-150mm: Fe≥Φ1.0mm, Non-Fe≥Φ1.5mm, SUS≥Φ2.0mm

H-200mm: Fe≥Φ1.2mm, Non-Fe≥Φ2.0mm, SUS≥Φ2.5mm

Effective detection hole width: 150-1000mm customized according to requirements

Effective detection hole height: 80-500mm customized according to requirements

Maximum speed of conveyor belt: 25m/min

Conveyor belt material: food grade PU belt

Protection class: IP65

Display and operation mode: LED falt key input

Machine weight: about 120kg

Power requirements: AC220V 50HZ

Power: 200W

Alarm mode: metal detection, alarm belt stop or automatic removal

Dimensions: about L1500×W850×H950mm

1. Adopt intelligent recognition technology, with self-learning and memory functions.

2. The detection effect is good and equipped with an anti-interference system to reduce the impact of other factors.

3. Continuous working, strong and durable.

4. Shockproof and waterproof design, dustproof and waterproof, can adapt to harsh working environments.

5. Carefully developed using leading digital technology and imported chips, it has the characteristics of high detection accuracy and stable performance.

6. Simple and friendly operation interface, using conversational LCD screen, ensuring extremely high detection accuracy with one setting.

7. It can be customized according to customer requirements and automatic rejection equipment is optional.

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

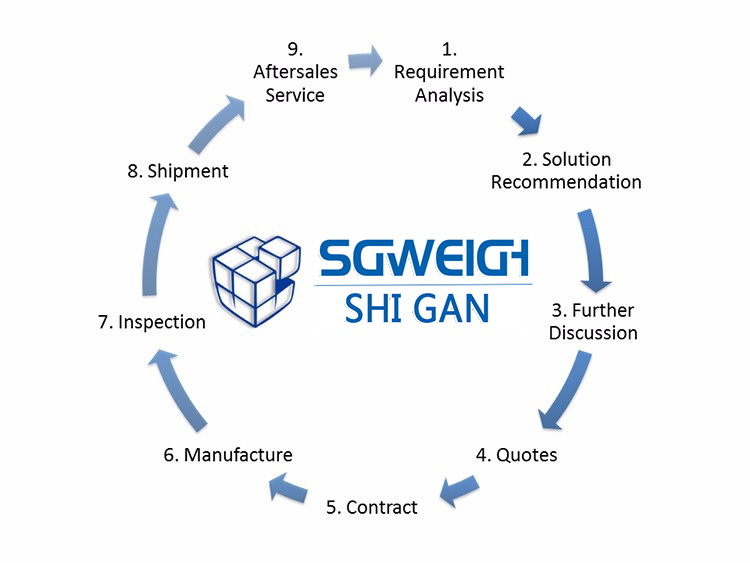

★Pre-sales

project design,performance introduction,technical agreement,contract signing,production testing and we can customized production according to your requirements.

★In-sales

we will provide you with the latest process in the product assembly,packing and transportation.

★Installation

◎We provide videos and instruction manual to show the process of installation.

◎We provide training for installation for free in our factory.

◎We can send technician to buyer's factory to install the machine and provide training service.

★After-sales

◎ For our machines, we will provide some spare parts and easy broken parts free of charge when delivering.

◎We will have one year free warranty period.During warranty period,if there is any malfunction for the machine,we will try our best to solve the problem within 24 hours.If there are some spare parts needed to be replaced, we will provide the spare parts for free.Beyond warranty, we will charge the cost price for spare parts.