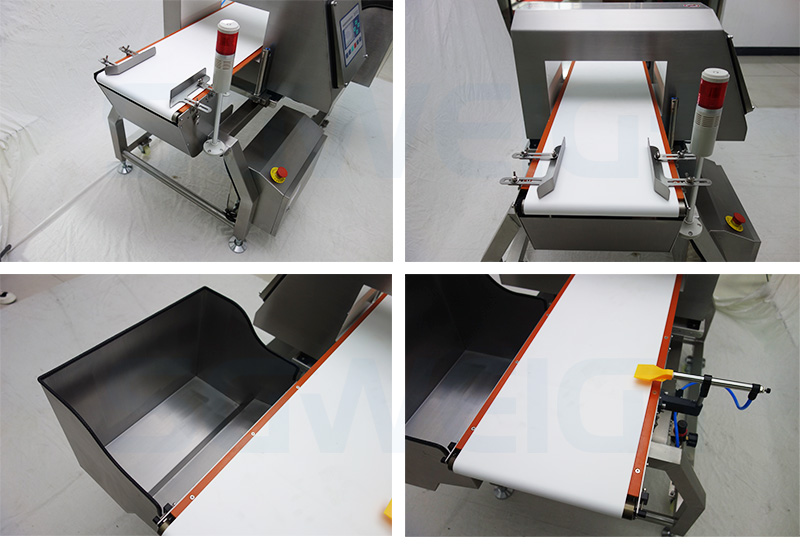

Automatically Reject Unqualified Products Metal Detector Machine For Food and Cloth is a device used to detect the presence of metal contaminants in products or materials.Welcome to consult for quotation information !

SG-M400

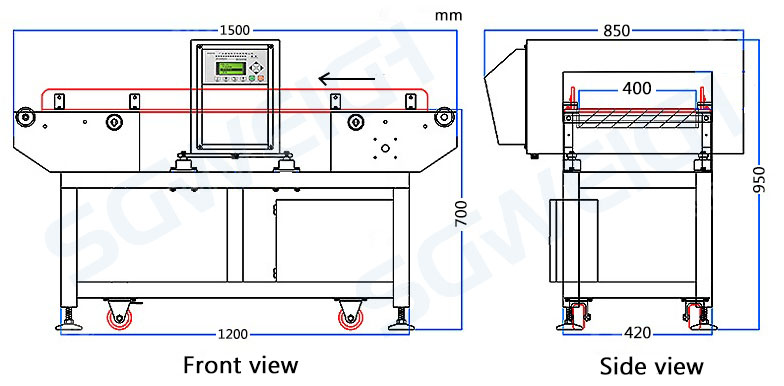

Effective detection hole width: 150-1000mm customized according to requirements

Effective detection hole height: 80-500mm customized according to requirements

Maximum speed of conveyor belt: 25m/min

Conveyor belt material: food grade PU belt

Protection class: IP65

Display and operation mode: LED falt key input

Machine weight: about 120kg

Power requirements: AC220V 50HZ

Power: 200W

Alarm mode: metal detection, alarm belt stop or automatic removal

Dimensions: about L1500×W850×H950mm

For reference only, please consult for details!

Contact us to recommend a product that is suitable for you!

1.Electromagnetic Field: Metal detectors emit an electromagnetic field around a coil or antenna. When a metallic object passes through this field, it disturbs the field and induces electrical currents in the metal object.

2.Detection Circuitry: The metal detector contains electronic circuitry that analyzes the disturbances in the electromagnetic field caused by the presence of metal.

3.Alarm System: If the disturbance surpasses a certain threshold, indicating the presence of metal, the metal detector triggers an alarm to alert operators or automated systems.

4.Adjustable Sensitivity: Metal detectors often have adjustable sensitivity settings to customize the detection threshold based on the type and size of metal contaminants expected in the inspected materials.

5.Integration: Metal detectors can be integrated into production lines, conveyor systems, or used as standalone units depending on the application and requirements.

6.Rejection System: In applications where product quality is critical, metal detectors may be paired with rejection systems to remove contaminated products from the production line automatically.

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.