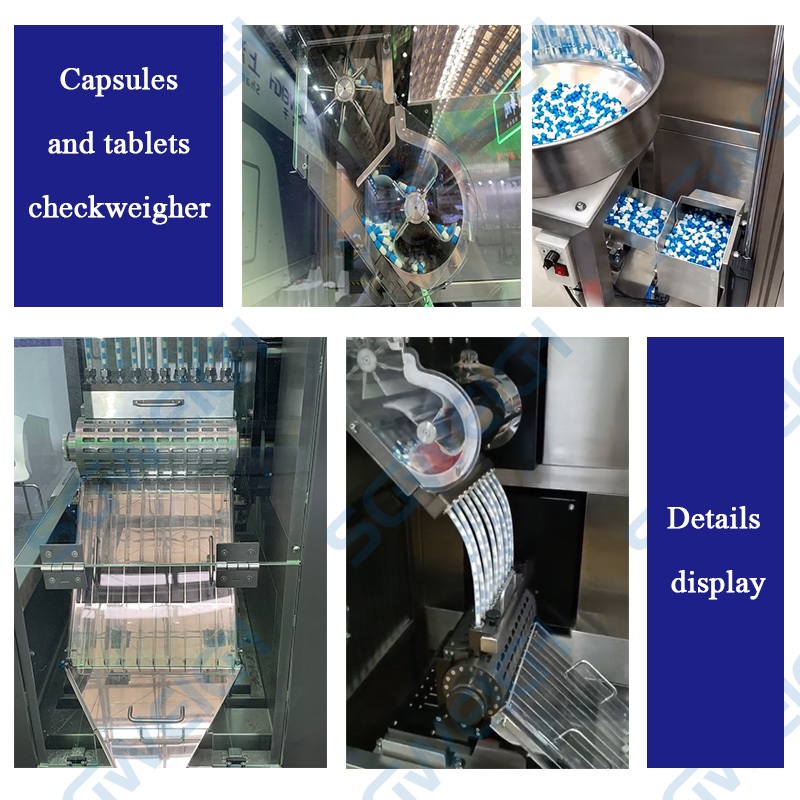

Capsule Tablet Checkweighers are high-precision weighing systems designed to automatically check the weight of individual tablets, capsules, or small pharma units in production.They ensure every product meets the specified weight limits and comply with GMP/FDA requirements.

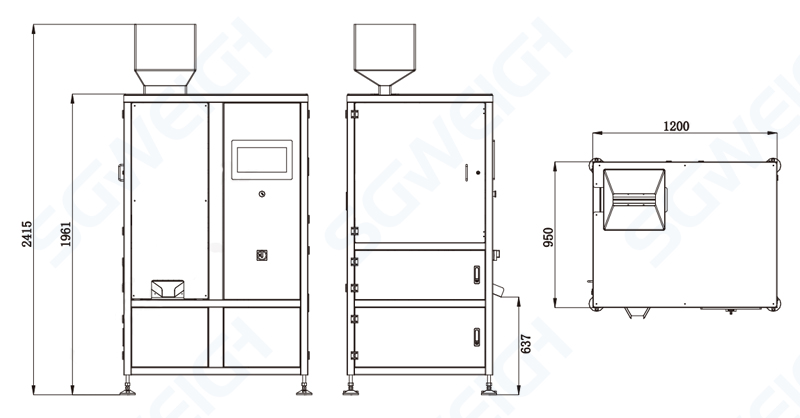

Type:SG-JN10/SG-JN20/SG-JN3O

Weighing scope:5-2000mg

Display scale:0.1mg

Highest sorting accuracy:±0.5mg

Product specification:Capsule-00#-5#/Wafer-Φ5.5-Φ18mm/Thickness-3-12mm/Pill-Φ5.5-Φ12mm(Other sizes or shapes subject to testing)

Highest sorting ability:100000 PCS/HR/200000 PCS/HR/300000 PCS/HR

Number of columns:10 Columns/20 Columns/30 Columns

Power supply:AC-220V±10%, 50HZ

Compressed air:0.3-0.9Mpa

Use environment:15~30°C (The temperature change during use should not exceed the range of 1°C/h.Humidity:30-70%(but no condensation)

Weight of Machine :350kg/500kg/700kg

Shell material:SUS304

You can select the best suitable model depending on the production volume.

◎ Large display for clear viewing and easy operation.

◎ Default Chinese and English user interface.

◎ Suitable for standard capsules and tablets.

◎ Displays relevant data for each channel.

◎ Three-level operation permission management with customizable passwords.

◎ 100 preset product recipes can be stored.

◎ All channels can be cleaned without disassembly.

◎ Multiple channels for improved production efficiency (customizable number of channels).

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

TAGS