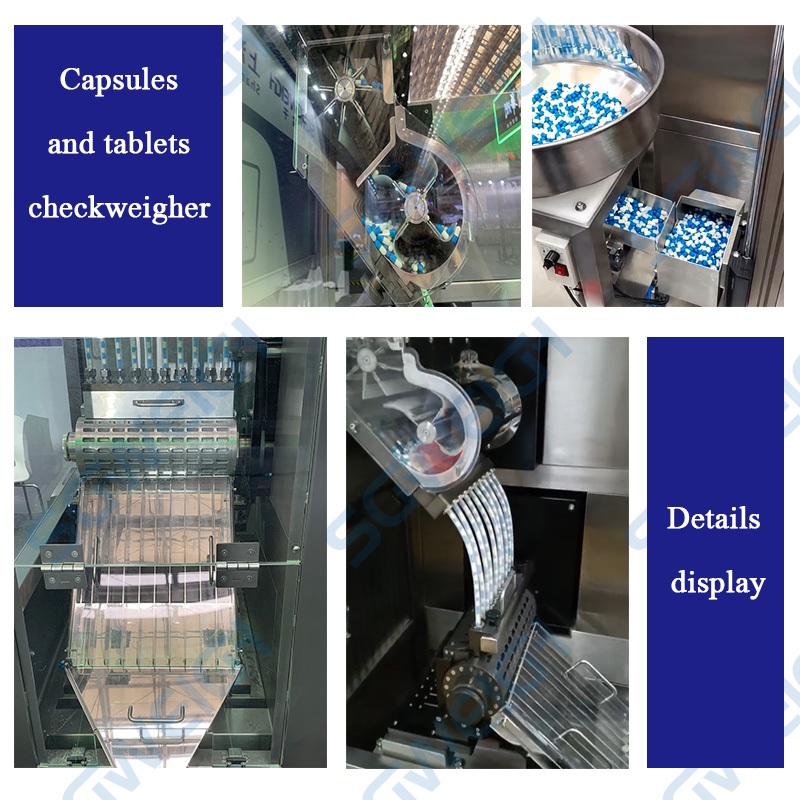

The 24-lane Capsule Checkweigher is a high-precision, high-speed online multi-channel weight detection device designed specifically for capsule products (such as hard and soft capsules) in the pharmaceutical industry. It can simultaneously process the weight of capsules from 24 parallel channels.

240K PCS/H High-Capacity Capsules Checkweigher is mainly used at the end of automated production lines to perform real-time weight detection on each batch of capsules, rejecting overweight, underweight, damaged, or incomplete capsules.

Type:SG-JN24

Weighing scope:5-2000mg

Display scale:0.1mg

Highest sorting accuracy:±0.5mg

Product specification:Capsule-00#-5#/Wafer-Φ5.5-Φ18mm/Thickness-3-12mm/Pill-Φ5.5-Φ12mm(Other sizes or shapes subject to testing)

Highest sorting ability:200,000-240,000 PCS/HR

Number of columns:24 Columns (Customizable)

Power supply:AC-220V±10%, 50HZ

Compressed air:0.3-0.9Mpa

Use environment:15~30°C (The temperature change during use should not exceed the range of 1°C/h.Humidity:30-70%(but no condensation)

Shell material:SUS304

1. Multi-channel Parallel Detection

● 24 channels operate simultaneously, significantly increasing throughput;

● Can be integrated with high-speed capsule filling/tableting machines and automated dispensing lines;

● Suitable for the high-efficiency detection needs of large-scale pharmaceutical production lines and OEM/contract manufacturing lines.

2. High-Speed, High-Precision Weighing

● Employs high-precision weighing sensors and intelligent filtering algorithms;

● Achieves ±0.5 mg level accuracy (depending on model/settings);

● Maintains stable readings even at high speeds.

3. Automatic Rejection and Classification

● Sets upper and lower weight thresholds;

● Automatically rejects or classifies substandard capsules.

4. Intelligent Control and HMI Operation

● Touchscreen control interface supports rapid parameter setting;

● Visualized presentation of data statistics, trend charts, alarm logs, etc.;

● Supports formula management and adapts to different capsule sizes.

5. Integration with upstream/downstream equipment

● Compatible with:

● Capsule filling machine

● Tablet press

● Automated cartoning/filling and sealing production line

● Achieve fully automated quality control.

Our machines is fully tested and calibrated before delivery.

It is packed in a strong wooden case with internal shockproof protection.

Various shipping options are available — by sea, air, or land — ensuring safe and on-time delivery by professional logistics partners.