SG-450 Checkweigher is designed for testing the weight of individual products and is widely used in industries such as electronics,pharmaceuticals, food and beverages,health products, daily chemicals,light industry, and agricultural and sideline products.

Type:SG-450

Weighing Range:0.05-20/30kg

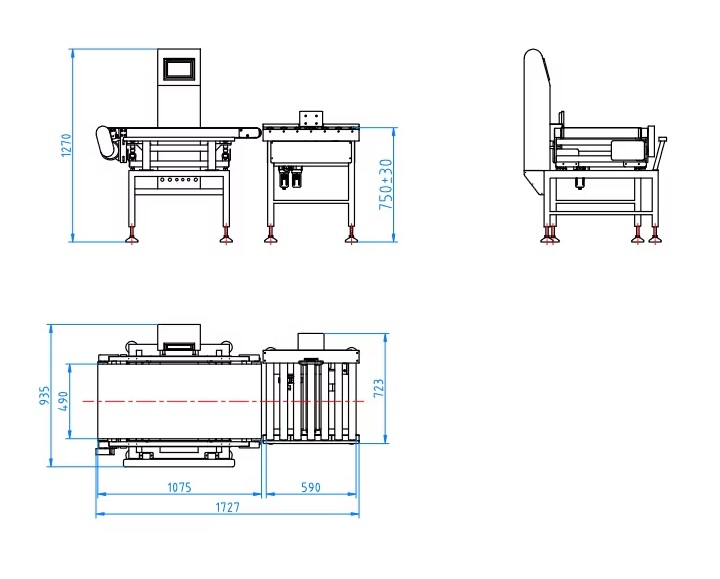

Limited of product:L: 550 W:450 H: 3-400mm

Accuracy:±5/10g Depend on products

Division Scale:0.1g

Belt Speed:0-60 m/min

Max Speed:40 pcs/min

Belt Width:450mm

Machine Weight:40+70+45kg

Power Supply:AC 110/220V ±10% 50HZ

Power:400W

Main Material:SU304 stainless steel

1. Weight detection

Dynamic weighing: During the operation of the production line, the weight of the product passing through the conveyor belt is measured in real time without stopping.

2. Weight classification

Weight interval division: According to the preset weight range, the products are divided into different categories (such as qualified, overweight, and underweight).

3. Rejection of unqualified products

Automatic rejection: Automatically remove overweight or underweight products from the production line through pneumatic push rods, swing arms, diversion devices, etc.

4. Data statistics and analysis

Real-time data recording: Record the weight data of each product for quality traceability.

Statistical analysis: Generate statistical reports such as weight distribution diagrams, qualified rates, and unqualified rates to help optimize the production process.

5. Alarm function

Over-limit alarm: When the product weight exceeds the preset range, the equipment will issue an audible and visual alarm to remind the operator.

Fault alarm: When the equipment fails, it will automatically alarm and shut down.

6. Integration with production line

Automation control: Link with other equipment on the production line (such as filling machines and packaging machines) to achieve fully automated production.

7. Friendly interface

Flexible parameter settings: different weight ranges, rejection times and other parameters can be set according to different products.

Inner use the plastic wrapping ,out package will use stronger wooden cases.

Our standard package process:

1) Dust & Cleaning

2) Lubricate Drive Parts

3) Divide Machine Into Modules

4) Wrap Modules With Plastic Film

5) Packing Modules into Plywood Cases

6) Mark Shipping Mark In The Cases

If any special requirements, we will pack it as requested.