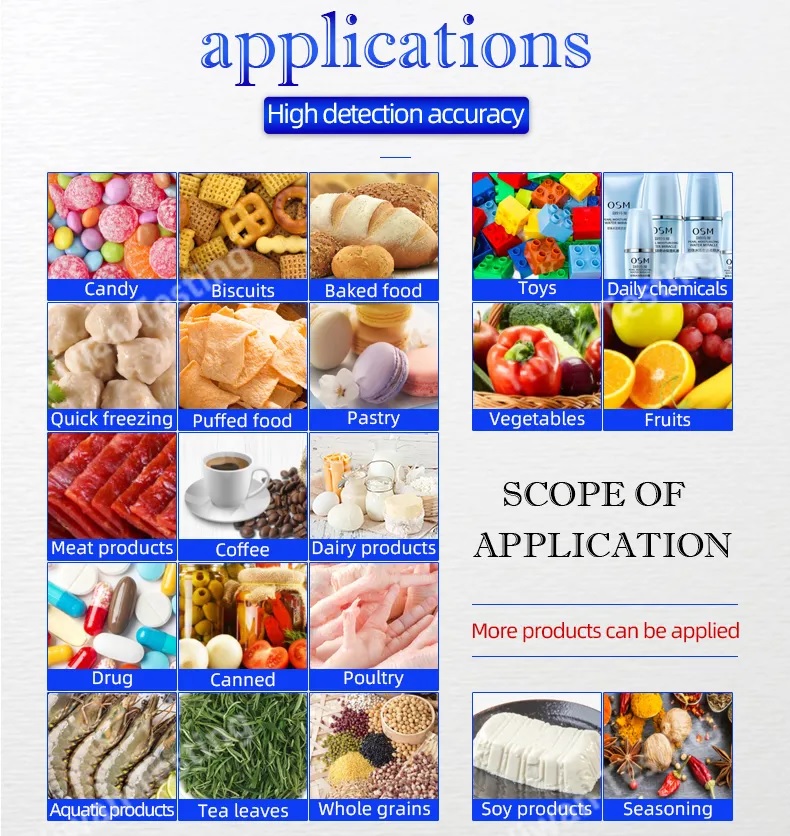

0.5-50Kg Dynamic Conveyor Weighing Machine can check packing products’ weight online whether their weights are overweight or less-weight. At the same time,check weight machine can check products’ quantities or attachment whose package is bag,box,can,bottle,carton etc to see whether products lack something or not.Using Checkweigher for Big Heavy Cartons Bags can ensure products’ net weight,quantities accord with standard and requirements,enhance products’ quality and integrity, save costs and avoid customers’ complaints.

Type SG-600

Weighing Range 0.5-50Kg

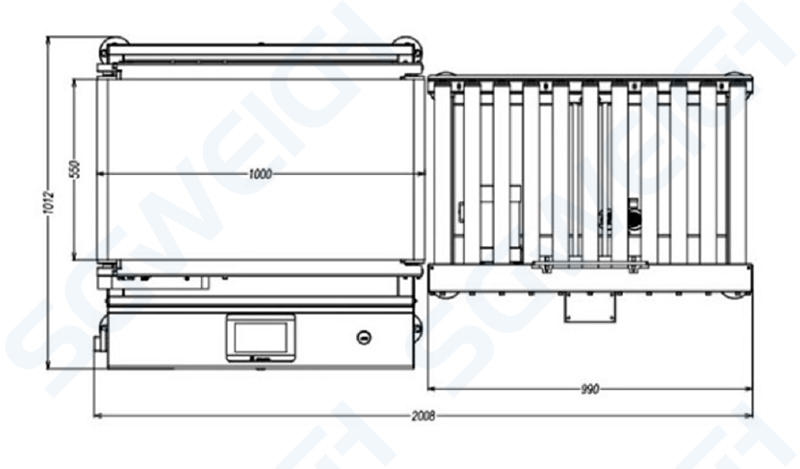

Limited of product L: 800 W:600 H: 3-400mm

Accuracy ±20g Depends on product

Division Scale 1g

Belt Speed 0- 40 m/min

Max Speed 30 pcs/min

Belt Width 600mm

Machine Weight 80+50kg

Power Supply AC 110/220V ±10% 50HZ

Power 500W

Main Material SUS304 stainless steel

For reference only, please consult for details!

Contact us to recommend a product that is suitable for you!

1.Versatility: Standardized machine structure and standardized man-machine interface can complete the weighing of various materials;

2.Easy to replace: can store a variety of formulations, convenient for the replacement of product specifications;

3.Simple operation: the use of Weilen color man-machine interface, the whole intelligent, user-friendly design;

4. Easy to maintain: The conveyor belt is easy to disassemble, easy to install, maintain and clean;

5. Adjustable speed: adopt variable frequency control motor, speed can be adjusted according to needs;

6. High-speed, high-precision: adopt the high-precision digital sensors;

7. Zero tracking: can be manually or automatically cleared, and dynamic zero tracking.

8. Can combine with metal detector, labeling machine.

Checkweigher can be widely used in electronic hardware, pharmaceutical, food, chemical, beverage, health care products, printing, light industry, agricultural and sideline products, express logistics filed etc.

1.Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Packing Detail:

1.Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

2.We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.